Streamline your blade Inspections through our

high-quality inspection services

Find out how our AI powered BLADE PATROL™ Technology reduces your expenses.

Our BLADE PATROL™ Technology support your needs by checking the condition of your wind turbine blades, inspecting a wind farm for possible warranty claims or looking to increase the efficiency of your blades, BLADE Patrol™ offers you an innovative and efficient solution for inspecting and controlling your blade assets.

Cost Reduction

BLADE POWER drives down costs by providing a external blade inspection for an onshore wind turbine in just 15 minutes on average, and verifies the image quality during inspection flights to minimise re-flights and turbine downtime.

If we detect a serious blade damage during an inspection flight, we will notify our customers on the same day. Our blade repair teams can also repair major blade damages in the shortest possible time while working with our fully covered blade repair platforms type TERRA, to avoid the effects of the bad weather conditions and reduce turbine downtime.

Data accuracy and quality

BLADE POWER improves data accuracy by intensively training our UAV and ROV inspection pilots in the handling and operation of the inspection technology used on site.

This trainings improves our inspection capabilities over a wide range of mission types and, in combination with our advanced autonomous flight controls, ensures that inspections can be carried out in wind speeds of up to 15 meters per second, while maintaining the same high quality of inspection results.

Data Consistency

BLADE POWER improves data consistency by Implementing multi-step quality control processes for image analysis together with implementing AI tools to avoid errors and enhance analysis quality and consistency.

Consistently capturing blade data annually is essential to detect blade damage progression and analyse tendencies in your wind turbine fleet.

Comprehensive reports for reliable O&M decisions

BLADE POWER provides you with detailed and inspection reports with clear and analyzed information's, that's allow you to made informed O&M decisions to optimize blade maintenance costs and reduce turbine downtime.

Our detailed inspection reports can be viewed by our customers blade management platform

BLADE VIEW™, which equipped with various damage evaluation processes, provides you with a clear picture of the condition of the blades and recommendations for optimization.

Advanced inspection solutions to performing efficient

EXTERNAL BLADE INSPECTIONS

BLADE PATROL™ - EXTERNAL BLADE INSPECTION DRONE

Our experienced UAV Pilots inspect blades on with our custom designed BLADE PATROL™ inspection drones, combining with an specially developed autonomous Flight Intelligence System for automated real-time, high-quality image data acquisition.

The high-quality images and data are achieved by real-time adaptive calculations that keep the drone at an optimal distance from the wind turbine blade.

External blade inspections are necessary to maintain and extend the lifetime of the blades. The use of UAV is a time and cost-efficient technology, compared to the method of exterior blade inspections performed by technicians that require the use rope access technic.

At the same time, we avoid the risk of accidents when using the technicians rope access technology.

BLADE PATROL™ - LPS TEST DRONE

Wind turbine Lightning Protection Systems (LPS) can suffer damage from lightning strikes. Regular maintenance and inspections are vital to ensure the continued effectiveness of LPS in protecting wind turbines from lightning-related damage.

Our experienced UAV pilots perform LPS inspections under using specially designed BLADE PATROL™ Lightning Protection System (LPS) measuring drones.

LPS inspections are necessary to maintain the function of the Lightning Protection Systems (LPS) at the blades. The use of UAV LPS inspections is a time and cost-efficient technology, compared to the method of exterior blade LPS inspections performed by technicians that require the use rope access technic.

Advanced inspection solutions to performing efficient

INTERNAL BLADE INSPECTIONS

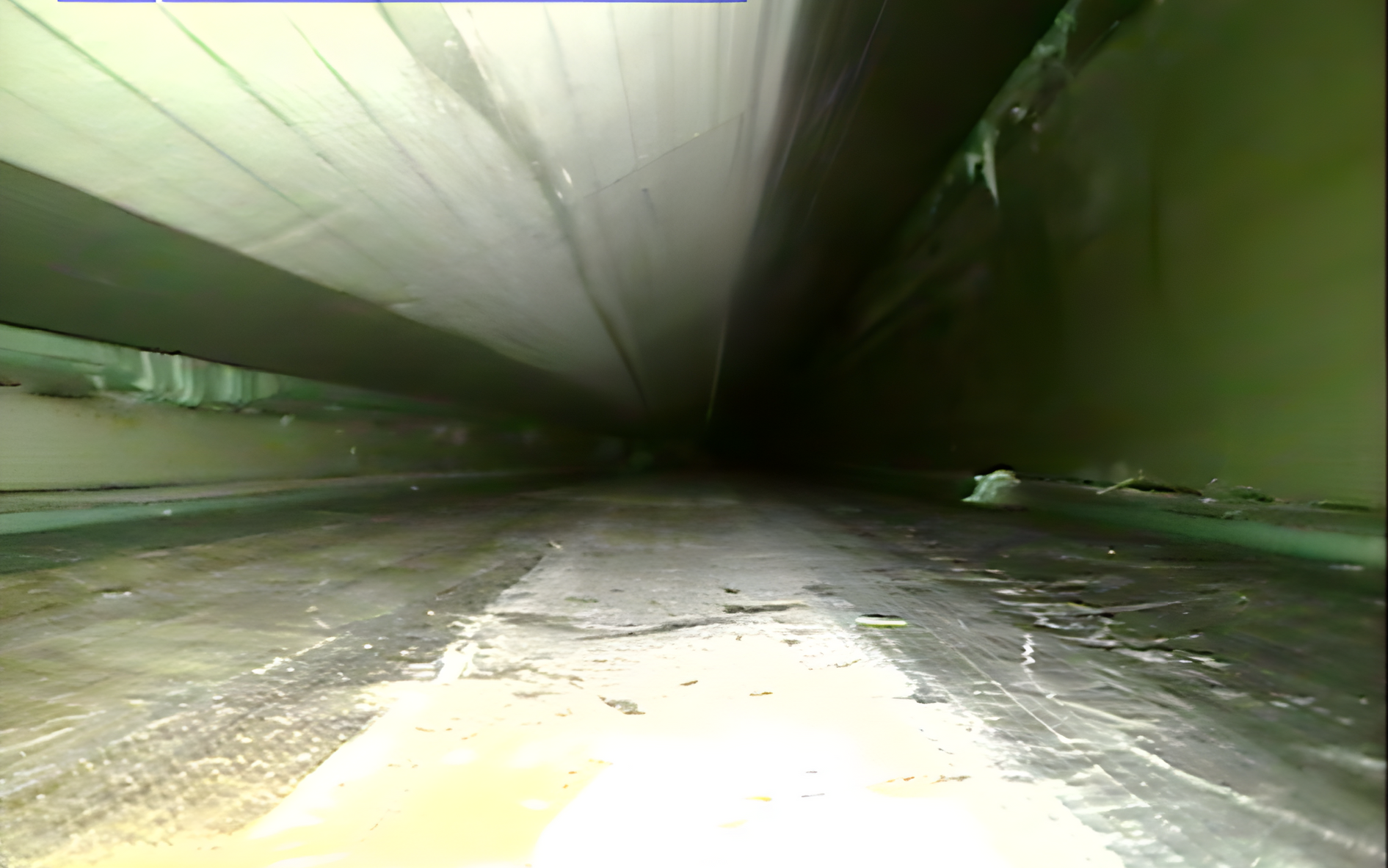

BLADE PATROL™ - INTERNAL BLADE INSPECTION CRAWLER

The rotor blades of wind turbines are designed for durability and resistance under very extreme conditions. The internal inspection of the blades is therefore also crucial as the external blade inspection to maintain and extend the lifetime of the blades.

Our experienced ROV (remotely operated vehicle) inspection specialists perform internal blade inspections under using BLADE PATROL™ advanced robot crawler systems, to detect changes in the internal structure, such as delamination, cracks, at an early stage and avoid turbine downtimes.